Primarily intended to protect against soiling, work clothes also enhance the image of companies (personalization and standardization for all staff) and are often real tools for improving work, thanks to their functionality.

Protective clothing, on the other hand, protects against specific risks and is subject to standards.

Many garments today offer protection against several risks at the same time. Technicality, quality, functionality, versatility, design, ergonomics, comfort are today basic requirements for the protection of the body.

What are the risks?

workers can face many risks:

- Mechanical : cuts, shocks,…,

- Chemical : dust, splashes or projections of chemicals, ...,

- Organic : contamination by a virus, bacteria,…,

- Thermal : cold, heat, splashes of molten metal,…,

- related to radioactive contamination,

- related to bad weather,

- related to the accumulation of electrostatic charges,

- linked to poor visibility,

- linked to an electric arc.

How to choose the right protection?

you need to determine:

- the risks you run (chemical, thermal, mechanical, electrical, etc.),

- constraints related to your job, your environment and your working conditions (gestures, postures, ambient temperature, use of machines, driving a vehicle, etc.),

- your needs in terms of comfort and ergonomics (waterproof-breathable garment, loose or fitted cut, modern design, etc.).

the general requirements for protective clothing are defined in the standard in 340: 2004. it is supplemented by other standards, depending on the type of protective clothing.

the different types of protective clothing

Protective clothing against bad weather and cold:

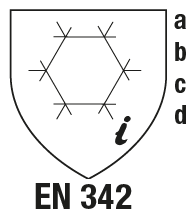

EN 342: 2005 protective clothing - sets of clothing and articles of clothing for protection against the cold.

Required performance: protection against cold environments - humidity and wind at air temperature below -5 ° C.

the pictogram is accompanied by four values:

a : Value of basic resultant thermal insulation measured on a mobile mannequin (icler), in m2k / w + (type of underwear).

b : Value of the resulting thermal insulation measured on a fixed mannequin (icler), in m2k / w + (type of underwear) optional.

types of underwear:

B = reference underwear for outfits and combinations: shirt with long sleeves, long pants, additional thermal underwear, socks, felt slippers, knitted gloves, balaclava.

C = underwear specified by the manufacturer.

R = reference underwear when only a jacket or pants is measured. in this case, the additional thermal underwear is replaced by a shirt and light work clothes. the icler value of all these underwear is +/- 0,185 m2k / w.

c : Air permeability class AP in mm / s (from 1 to 3) the higher the value, the less the product is permeable to air and protects from the wind.

d : Water penetration resistance class WP in pa / min (from 1 to 2; 2 indicating the best tightness) - optional.

An x indicates that the test has not been performed.

A 0 indicates that the product did not obtain the minimum score in this test.

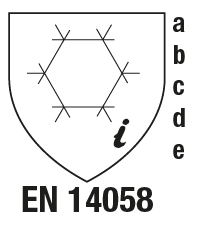

EN 14058: 2004 protective clothing - articles of clothing for protection against cool climates.

Required performance: light protection against cool climates - humidity and wind at an air temperature of -5 ° C or above.

the pictogram is accompanied by five values:

a: Thermal resistance class rct (from 1 to 3; 3 indicating the best thermal insulation).

b: Air permeability class ap in mm / s (from 1 to 3; 3 indicating the best protection against the wind) - optional.

vs :Class resistance to water penetration Wp in pa / min (from 1 to 2; 2 indicating the best tightness) - optional.

d: Value of the resulting basic thermal insulation measured on a mobile mannequin (Icler) in m2 K / W + (type of underwear) - optional.

e: Value of the resulting thermal insulation measured on a fixed mannequin (Icle) in m2 K / W + (type of underwear) - optional.

An X indicates that the test has not been performed.

A 0 indicates that the product did not obtain the minimum score in this test.

EN 343 + A1: 2007 Protective clothing - Protection against rain.

The pictogram is accompanied by two values:

- top right = water resistance class (from 1 to 3; 3 indicating the best impermeability).

- bottom right = breathability class (from 1 to 3; 3 indicating the best breathability).

High visibility protective clothing

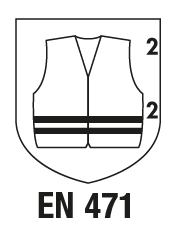

EN 471 + A1: 2008 High visibility signaling clothing for professional use - test methods and requirements

For these garments, the pictogram is accompanied by two values:

- top right : clothing class, based on the minimum surface area of fluorescent and retro-reflective materials (from 1 to 3; 3 indicating the most demanding in terms of visibility).

1 class : unsuitable for work along public roads.

2 class : road works with a maximum speed of 50km / h.

3 class : along the tracks where a speed higher than 50 km / h is authorized.

- at the bottom right : index of photometric performance class of retro-reflecting materials (from 1 to 2; 2 indicating the best reflection performance).

Protective clothing against mechanical risks:

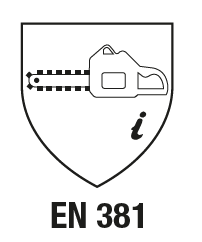

EN 381-5: 1995 Protective clothing for users of hand-held chain saws - requirements for leg guards.

EN 381-2: 1995 test methods for leg protectors.

It exists three types of leg protection:

The types A and b provide protection primarily to the front of the legs and are intended for use by professional foresters who have been informed and trained.

type c offers protection to the front and back of the legs and is intended for use by non-professionals or in more extreme conditions (working at height for example).

There are also three classes, depending on the speed of the chain during the test:

- 1 class : 20 m / s

- 2 class : 24 m / s

- 3 class : 28 m / s

EN 381-11: 2003 Protective clothing for users of hand-held chain saws - requirements for protective vests

EN 381-10: 2003 test methods for protective jackets

There are four classes depending on the speed of the chain during the test:

- 0 class : 16 m / s

- 1 class : 20 m / s

- 2 class : 24 m / s

- 3 class : 28 m / s

EN 510: 1993 Specifications for protective clothing against the risk of being caught by moving machine parts

Protective clothing against heat and flame

EN iso 11611: 2008 Protective clothing for use in welding and allied processes - replaces EN 470

They can be worn on an 8 hour day at normal temperatures.

s offer protection against small splashes of molten metal, short-term contact with a flame and radiant heat from the arc.

They must provide a certain degree of electrical insulation, in the event of accidental contact with an electrical conductor at a voltage greater than approximately 100 V DC, under normal welding conditions.

It exists two protection classes:

- class 1: protection against low risks during welding techniques (only small projections and low radiant heat).

- applications: gas, TIG, MIG, microplasma, spot welding,

MMA (with rutile electrode) - milling.

- class 2: protection against greater risks in welding techniques (larger splashes and higher radiant heat).

- applications: MAG, MIG (high current), arc, MMA (with basic or cellulosic electrode) welding - plasma cutting - oxygen cutting - gouging.

Depending on the method used to test the product for flame propagation, the class will be followed by A1 in a horizontal conflagration and A2 in a lateral conflagration.

EN iso 11612: 2009 Protective clothing against flame and heat emitted by convection and radiation - replaces standard EN 531 (except those for welders and firefighters).

They can offer protection against short-term contact with a flame, against contact heat, heat emitted by convection or radiation, against splashes of molten metal and sometimes even against water (optional).

The pictogram is accompanied by letters (depending on the test performed) followed by a number (depending on the test method or the test result):

A: flame spread:

- A1: during a horizontal conflagration

- A2: during a side fire

B: convective heat (exposure time before reaching a temperature rise of 24 ° C) :

- B1: between 4 and 10 seconds

- B2: between 10 and 20 seconds

- B3: more than 20 seconds

C: radiant heat (exposure time before reaching a temperature rise of 24 ° C) :

- C1: between 7 and 20 seconds

- C2: between 20 and 50 seconds

- C3: between 50 and 95 seconds

- C4: more than 95 seconds

D: projections of molten aluminum:

- 01: from 100 to 200 grams

- 02: from 200 to 350 grams

- 03: more than 350 grams

E: projections of molten iron or copper:

- E1: from 60 to 120 grams

- E2: from 120 to 200 grams

- E3: more than 200 grams

F: contact heat:

- F1: between 5 and 10 seconds

- F2: between 10 and 15 seconds

- F3: more than 15 seconds

W: rain protection:

The W is followed by two numbers:

- the first corresponds to the waterproofing class (from 1 to 3; 3 indicating the best waterproofing).

- the second in the breathability class (from 1 to 3; 3 indicating the best breathability).

To comply with this standard, clothing must comply with: the flame propagation test (code A1 or A2) and at least one of the following five tests (codes B to F).

EN iso 14116: 2009 Protective clothing against heat and with limited flame spread - Materials, material assemblies and clothing with limited flame spread.

Made from flame retardant materials, these garments burn, but to a limited extent and go out when the flame is removed.

Depending on the result of the flame propagation test, there are three indices:

index 3: the material offers the best protection against the spread of flames. The igniting time and the blushing time is a maximum of 2 seconds.

No holes and no drops are formed.

index 2: the material extinguishes before the edge of the sample is reached. No maximum flashover time is required. The other points are similar to clue 3.

index 1: no hole is formed. Materials with index 1 cannot be worn on the skin.

Under the pictogram, next to the index can also be indicated: the number of washing, as well as the washing method and temperature; example: 25H / 30: 25 domestic washes at a temperature of 30 °.

h: household washing - i: industrial washing - vs : chemical washing

Protective clothing against chemical products :

there are three categories of risk:

- Category 1 - Minor risks

- Category 2 - Intermediate risks

- Category 3 - Serious or fatal risks

And six types of protection:

- Type 1: Gas tight clothing

- Type 2: Non-gas tight clothing

- Type 3: Protection against liquid chemicals in the form of jets (violent projection)

- Type 4: Protection against liquid chemicals in spray form

- Type 5: Protection against airborne solid chemicals

- Type 6: Protection against liquid chemicals in the form of small splashes

PB means that the protection of the body is partial.

EN 14605: 2005 + A1: 2009 Protective clothing against liquid chemicals - Performance requirements for garments whose connecting elements are liquid-tight

(type 3 = EN 466 or type Pb (3) = EN 467) or sprays

(type 4 = EN 465 or Pb type (4) = EN 467).

EN 13982-1: 2004 / A1: 2011 Protective clothing to be used against solid particles

Part 1: performance requirements of chemical protective clothing providing protection to the whole body against solid particles carried by the air (type 5).

EN 13982-2: 2005 Protective clothing to be used against solid particles

Part 2: test method for the determination of the inward leakage of fine particle aerosols in combinations.