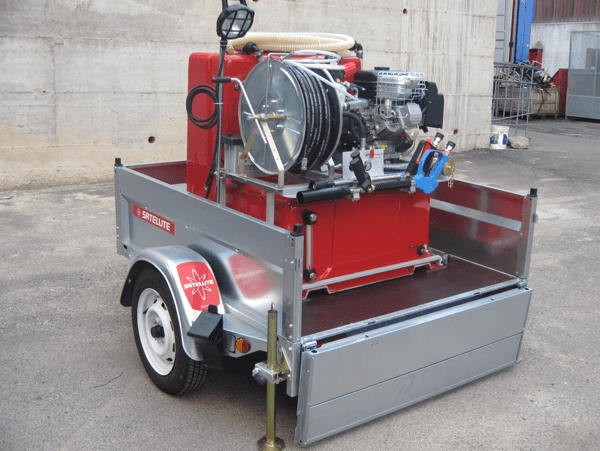

Fire protection trailer with high pressure pump + tank kits

Towable fire extinguishing kits with large capacity tanks

Fire protection modules fitted with high or medium pressure pumps are intended to be installed on trailers

Custom Made

performances

From 21 L / min. at 250 bar

Up to 135 L / min. at 20 bar

pumps diaphragm or piston

Engines Petrol or diesel

Tank from 100 to 2500 Liters

+ Hose reel, hose and lance

Further information

| Motor | Diesel gas |

|---|---|

| performances | 21 L/min. at 175 bars, 21 L/min. at 180 bars, 21 L/min. at 200 bars, 21 L/min. at 250 bars, 34 L/min. at 170 bars, 42 L/min. at 95 bars, 42 L/min. at 100 bars, 42 L/min. at 150 bars, 50 L/min. at 100 bars, 55 L/min. at 40 bars, 60 L/min. at 100 bars, 70 L/min. at 35 bars, 70 L/min. at 40 bars, 80 L/min. at 45 bars, 80 L/min. at 50 bars, 100 L/min. at 50 bars, 135 L/min. at 20 bars |

| Tank capacity (Liters) | 100, 200, 350, 400, 450, 500, 600, 1100, 1250, 1500, 2000, 2500 |

MEDIUM PRESSURE PUMPS

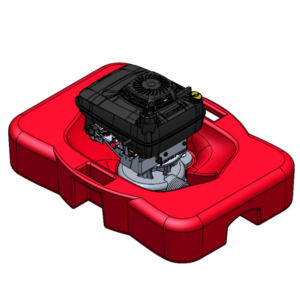

Gasoline diaphragm pump

Medium and high pressure pumps made from anodized aluminum in areas in contact with fluids. Max temperature 60 ° C. Petrol engines between 10 and 18 HP depending on the model.

|

Model |

Debit |

Max pressure |

Engime |

|

01B |

– 55 L/min |

– 40 Bar |

– 10 HP |

|

10B |

– 70 L/min |

– 40 Bar |

– 16 HP |

|

02K |

– 70 L/min |

– 35 Bar |

– 14 HP |

|

11B |

– 80 L/min |

– 50 Bar |

– 16 HP |

|

03K |

– 80 L/min |

– 45 Bar |

– 14 HP |

|

04B |

– 100 L/min |

– 50 Bar |

– 18 HP |

|

05B |

– 135 L/min |

– 20 Bar |

– 10 HP |

Diesel diaphragm pump

Medium and high pressure pumps made of anodized aluminum in areas in contact with fluids. Max temperature of 60 ° C. Diesel engines between 11 and 19 HP depending on the model.

|

Model |

Debit |

Max pressure |

Engime |

|

01D |

– 55 L/min |

– 40 Bar |

11 Hp |

|

02D |

– 70 L/min |

– 40 Bar |

11 Hp |

|

04D |

– 100 L/min |

– 50 Bar |

19 Hp |

|

05D |

– 135 L/min |

– 20 Bar |

11 Hp |

HIGH PRESSURE MOTOR PUMPS

Pump piston Gasoline

High and very high pressure 3 piston ceramic pumps in aluminum with brass cylinder head. Maximum temperature 60 ° C. Petrol engines between 14 and 23 HP depending on the model.

|

Model |

Debit |

Max pressure |

Engime |

|

61B |

– 42 L/min |

– 100 Bar |

– 16 HP |

|

50K |

– 42 L/min |

– 95 Bar |

– 14 HP |

|

51B |

– 42 L/min |

– 150 Bar |

– 18 HP |

|

52B |

– 34 L/min |

– 170 Bar |

– 18 HP |

|

54B |

– 21 L/min |

– 200 Bar |

– 16 HP |

|

57B |

– 50 L/min |

– 100 Bar |

– 18 HP |

|

070B |

– 21 L/min |

– 180 Bar |

– 16 HP |

|

59K |

– 21 L/min |

– 175 Bar |

– 14 HP |

|

60B |

– 21 L/min |

– 250 Bar |

– 16 HP |

|

62B |

– 42 L/min |

– 100 Bar |

– 18 HP |

|

66B |

– 70 L/min |

– 90 Bar |

– 23 HP |

|

68B |

– 60 L/min |

– 100 Bar |

– 23 HP |

|

62B |

– 42 L/min |

– 95 Bar |

– 14 HP |

Diesel piston pump

High and very high pressure 3-piston ceramic pumps in aluminum with brass cylinder head. Maximum temperature 60°C. 19 HP gasoline engines.

|

Model |

Debit |

Max pressure |

Engime |

|

50D |

– 42 L/min |

– 100 Bar |

– 19 HP |

|

51D |

– 42 L/min |

– 150 Bar |

– 19 HP |

|

52D |

– 34 L/min |

– 170 Bar |

– 19 HP |

|

57D |

– 50 L/min |

– 100 Bar |

– 19 HP |

|

60D |

– 21 L/min |

– 250 Bar |

– 19 HP |

Ready-to-install kits consist of:

- Water tank from 100 to 2500 Liters in Fiberglass construction in the shape of a cube.

- Fire engine with motor

- 1 or 2 manual or electric reels up to 100m of hose

- HP submachine gun water lance

- Chassis receiving all these elements

1 • MAXIMUM LIGHTNESS: with the GRP tank, the weight is lower than those built with another material (stainless steel) by about 50%, thus allowing to have a reduced load, or at equal weight, to increase the water capacity on the vehicle.

2 • RESISTANCE: the mixture of fiberglass fabric and resin, guaranteed with current technology better strength compared to other materials, and is easier to repair in the event of an accident (the same technology used as for racing cars, regatta boats and planes).

3 • PRODUCT / PRICE REPORT: with GRP tanks there is a cost reduction which affects the price of the final product.

4 • MONOLITHIC TANK.

5 • EXTINGUISHING AUTO TANK.

Through the new working methods of PRFV (Glass Fiber Reinforced Plastics), it has been possible to develop products with radically different shapes and structures and to be able to make them MONOLITHIC (one piece). This novelty has eliminated the big drawback of insufficient mechanical resistance to transverse and centripetal thrusts which occur in all other tanks not developed with this method. Indeed the “old” working method foresees the construction of 2 half-shells united by a peripheral gluing. This system has the disadvantage of being less resistant to the torsions created by a chassis on difficult terrain. The new technology makes it possible to build one-piece tanks with homogeneous and continuous ribs over the entire height of the sidewalls and, at the same time, to make them slightly conical. The bottom, placed in the same room and equipped with 50 mm ribs reinforced with high density polyurethane, fits into the body of the tank and the whole is laminated with fiberglass on the outside and on the outside. the interior all around the perimeter which becomes, after polymerization, a single body.

The resins used are of the FR type, self-extinguishing, according to the standards:

- DIN 53438 Teil 3 - Classification F 1/37 m / m

- FIAT 50433 - Classification INFLAMMABLE

- FIAT 50433/01 - Classification NOT INCANDESCENT IN FLAME

All of this kits are completely autonomous sets, ready to go.

Option:

- Foam spears

- Electric wire feeders or manual

- Panel for group orders

- Tank filling hydro-ejector

- Trailers

- Patented FHP foam proportioners

Fireco has developed the patented FHP foam blending system, which can overcome back pressure problems, due to the length of hose, that occur on classic blending models by Venturi. Our patented FHP system allows the operator to obtain the best performance even with 200 m of hose, while maintaining the right mix between water and foam. A special nozzle, capable of operating either with water or with a mixture, delivers a high quality foam close to the high expansion.

Detailed description of the complete module:

- submachine gun launcher with adjustment full jet ou broadcast Flow 40 L / min

- steel hose reel complete with 50 meters of PVC pipe for diaphragm pump and metallic R1 pipe for piston pump

- interchangeable cartridge filter positioned on the suction line

- tube too full pointing down

- Ø3 45-way valve with UNI 804 brass fitting for tank suction or external suction

- level by communicating vase

- manhole Ø330

- manual accelerator

- start and stop key

- second discharge outlet with quick coupling

- discharge valve for the main reel and for the second outlet

- operating lever, stop and pressure regulation

- pressure regulating valve

- pressure gauge

- spiral suction hose 6M with brass bottom valve UNI25 connection

- drain valve - use and maintenance booklet.

A selection of pumps adapted to your specific needs

Fire safety

Large range of firefighting and flood fighting motor pumps. Pumps can be skid-mounted, portable, or trailer-mounted

Marine - Sea water

Range of motor pumps resistant to sea water. Can be used for security services on ships and oil ports, commercial ports

Industrial building

Fire pumps are usually approved by a certification body and are powered by an electric or diesel engine or sometimes by a steam turbine.

Flood Construction site

Pumps used for lifting wastewater, evacuating loaded and muddy water, drying or irrigating.

Civil security

Motor pumps used during flooding to collect or drain water

Home Security

Motor pumps and a swimming pool to fight fires, as well as our range of cellar pumps intended for the evacuation of rainwater and clear water!